For many years,the air filter industry relied on the ASHRAE standard 52.1 as its technical and purchasing standard.In recent years,the air filter industry has changed important portions of this long-standing standard and now the ASHRAE standard 52.2,which is explained here, is the only ASHRAE stardard used to evaluate levels of efficiency and acceptable performance.

What is ASHRAE? The American Society of Heating,Refrigerating and Air-conditioning Engineers(ASHRAE) develops standards for both its 50,000 members and other professionals concerned with the design and maintenance of indoor environments.ASHRAE publishes standard for(1)Method of Measurement and Test,(2) Standard Design and (3)Standard Practice. ASHRAE has published a standard for testing air filters since 1968.The universally accepted standard used to evaluate product alternatives is fully titled ASHRAE standard 52.2-2007:Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size and is commonly refereed to as ASHRAE 52.2.Accredited by the American National Standards Institute (ANSI),it is a consensus standard , developed and published to define minimum values or acceptable performance.(www.ashrae.org) What happened to ASHRAE 52.1? ASHRAE 52.1 was the standard used to determine filter performance for several decades,but is now obsolete.The performance results of 52.1 were average dust-spot efficiency,average arrestance and dust holding capacity. A new standard,ASHRAE 52.2, was created to determine air filter efficiency as a function of particle size.The new rest method determines the ability of an air filter to remove dust by specific particle sizes ranging from 0.3 to 10 microns.This advancement led to the development of a Minimum Efficiency Reporting Value (MERV) for each filter tested.MERV is a central feature of ASHRAE 52.2 and was intended to replace the average dust-spot efficiency in ASHRAE 52.1. In order to replace 52.1, average arrestance and dust holding capacity were added to 52.2 under Addendum B,With this addition,ASHRAE 52.2 now contains the methods to determine the most significant values relating to filter performance. MERV performance is published for all HVAC filters manufactured by ZHUOWEI Air Filtration Products.

What is MERV? MERV, standing for Minimum Efficiency Reporting Value, is a guideline to determine a filters performance by particle size,ranging from 0.3 to 10 micron in size.This value is based on the lowest,orminimum efficiency for the filter.In many cases this is when the filter is first installed.

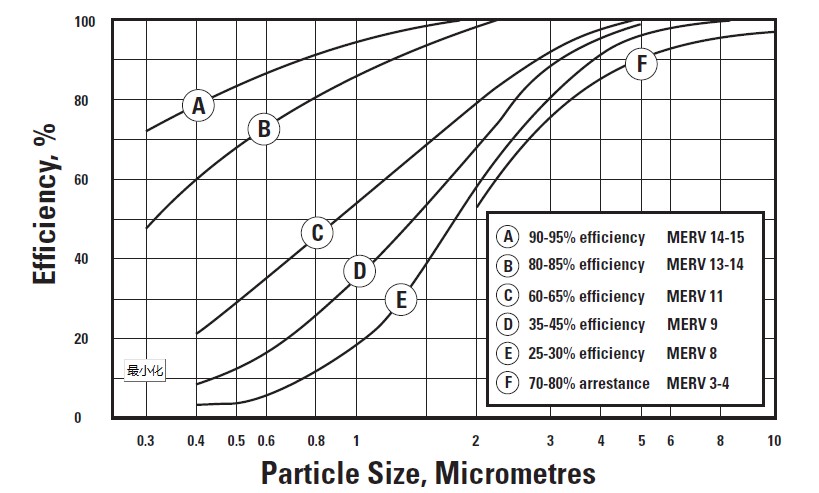

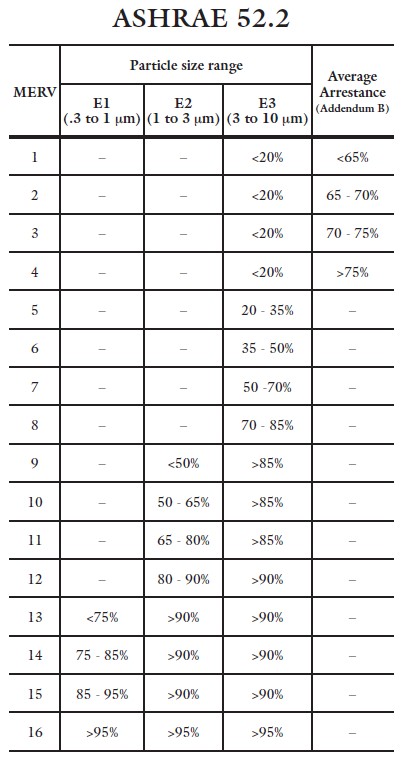

Generally, the higher the MERV, the better the filter will perform at removing smaller particle sizes.MERV 1 through 4 filters are designed to remove larger particle sizes.These filters are used to mainly protect equipment and are used in light commercial and residential applications.For these values, the average particle size efficiency from 3 to 10 micron is less than 20%.Because of this ,average arrestance , which is a measure of a filter's ability to remove coarse particulate, is used to determine MERV 1 through 4.The method to determine the average arrestance of a filter is found in Addendum B of 52.2. MERV 5 through 16 filters remove fine particles and are used in application where it is import to protect individuals or processes from airborn contaminants that could otherwise affect health and productivity.MERV 5 through 16 is determined by particle size efficiency.The average particle size efficiency in three ranges:E1(0.3 to 1 micron),E2(1 to 3 micron) and E3(3 to 10 micron) will determine MERV for these products.

This table above will show how average arrestance

and the three particle size efficiency ranges will determine MERV for a filter

ASHRAE 52.2 Conditioning Step In addition to establishing a method to determine filter performance by particle size,ASHRAE 52.2 includes an optional method called a conditioning step.This conditioning step is outlined in 52.2 under Appendix J. The conditioning step uses an aerosol to neutralize electrostatic charges on the filter media that could affect the MERV performance of a particular filter. When this method is used,a second filter (a companion to the filter tested in the main 52.2 test method) is run through the conditioning step and then tested for particle size efficiency, which is compared to the same efficiency guidelines that are used to determine MERV found in the table on the opposite page.The results of this test are reported as MERV-A and will normally be shown along with MERV on a filter report.

|