As it is publicly known and increasingly taken into account the Indoor Air Quality it is a topic of extreme importance to human health.

This is simple to explain when some facts are exposed:

- Humans spend 90% of their time indoors.

- Indoor air can be up to 50 times more polluted than outdoor air.

- An important part of the worldwide population lives and works in areas that exceeds the reference particle rates (for PM2.5) indicated by the World Health Organization (WHO). Poor indoor air quality is associated to physical symptoms such as headaches, fatigue, coughing, eye irritation, skin irritation, respiratory congestion, etc, and can cause problems related with comfort, job satisfaction, work performance and more severe health effects. When HVAC consultants are designing a system to effectively control the Indoor Air Quality (IAQ) for each building their first concern is to know the quality of the Outdoor Air (ODA) for each specific location and the Indoor Air (IDA) quality required for that specific building type. After this two parameters are known, alongside with indoor contamination sources, the type of filtration for the Air Handling Units can be selected. Parameters affecting the Indoor Air QualityThere are several parameters affecting the IAQ: - Outdoor climate;

- Outdoor and Indoor air contamination;

- Ventilation design;

- Ventilation maintenance;

- Temperature;

- Humidity;

- VOC's;

- Particles;

- Microbes;

- Etc. AHUs...the IAQ's best friend among the HVAC equipmentsAmong the HVAC equipments, the Air Handling Units are a very special case with unique features that differentiate them from all others and make them the most important equipment in a HVAC system installation.

AHUs are able to perform at the same time several critical functions for a building, such as: - Mechanical Ventilation (air change, supplying fresh air to the building and at the same time exhausting the contaminated air);

- Air temperature conditioning (cooling and heating);

- Air humidity conditioning (humidification and dehumidification);

- Air filtration, with several stages and different types of filters;

- Able to modulate the fresh air airflow according the IAQ reference values for VOC's and CO2 measured in the rooms (through sensors);

- Heat Recovery. As we can see 5 out of this 6 functions affect directly the indoor air quality making the Air Handling Units the true IAQ's best friend among the HVAC equipments. The Air Handling Units are the perfect place to install all the components to handle the air (such as fans, coils, filters, humidifiers, heat recovery systems, among others) because... - The casing is thermal insulated, reducing the risks of condensations that can generate, for example, mold health issues (as well as reducing energy loses);

- The casing is designed to have low air leakage between the outdoor air and the airstream inside the casing, and this way maintain the air after the filtration stages clean, without outdoor air infiltrations.

- Are designed to allow the access for cleaning, maintenance and replacement of all components. Access the components for maintenance and cleaning issues is vital to maintain the indoor air quality; Air Filtration as a vital featureOne of the most important function of the Air Handling Units concerning the IAQ is the air filtration. There are different types of air filters but in general they are divided in two main groups: Particulate Air Filters and Gas Phase Air Filters. Particulate Air FiltersThe particulate air filters can be divided in 3 main levels: - Primary, or coarse, filtration

- Fine filtration

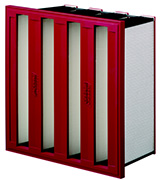

- Absolute Examples of the most used in Air Handling Units: Fibre media filters (glass, polymer, electrostatic charged), UV-C. Gas Phase Air Filters- "Purification" Examples of the most used in Air Handling Units: Activated carbon filters, photocatalytic Oxidation (PCO). Fibre filters are the most common filters installed on Air Handling Units, and the most used configurations are: - Pleated panel filters  Pleated Panel Filters. - Bag filters  Bag Filter. - Compact filters  Compact Filter. The nominal dimensions for the most used AHUs air filters, holding the frame, are: - 610 mm x 610 mm (face area = 592 mm x 592 mm)

- 610 mm x 305 mm (face area = 592 mm x 287 mm)

- 305 mm x 610 mm (face area = 287 mm x 592 mm)

- 305 mm x 305 mm (face area = 287 mm x 287 mm) In this second part of the article we will cover the following topics: filters standards, recommendations according hygienic issues, filters certifications and AHU filters selection (according to the EN13779). Filters StandardsEN779:2012This European standard classifies the air filters based on their lowest filtration efficiency (or minimum efficiency (ME)).

EN1822:2009This European standard classifies the high-efficiency filters. EN13779:2007This European standard specifies the required filter performance in a system to achieve good Indoor Air Quality (IAQ) taking into consideration the outdoor air.

ASHRAE 52.2This standard provides information about filter performance. It give us the efficiency as a function of particle size, as well as a the minimum efficiency reporting value (MERV).

Recommendations According Hygienic IssuesDue to hygienic reasons some recommendations should be followed, such as: - The use of two-stage particle filtration: 1st stage preferably F7, minimum M5; 2nd stage preferably F9, minimum F7.

- A minimum F7 class should be used if there is only one filtration stage.

- For the recirculation air a minimum M5 class filtration must be used to protect the system.

- For the extract/exhaust air a minimum M5 class filtration must be used.

- For the filter replacement 3 limits must be considered: time in operation, time installed and final pressure drop: 1st stage, 2000 hours or 1 year installed or final pressure drop is reached; 2nd/3rd stages, 4000 hours operation or 2 years installed or final pressure drop is reached; For exhaust/recirculated filters, 4000 hours operation or 2 years installed or final pressure drop is reached.

- The relative humidity always should stay below 90% and the average for 3 days should be less than 80%, to avoid microbial growth. Filters CertificationsWe will point out two examples of filter certification programmes: Eurovent CertificationApplies to Air Filter elements rated and sold as “Medium and Fine Filters Class M5, M6, F7 nad F9” as defined in the standard EN779:2012.

|