Absolute filters are used in places of highest requirements to the cleanliness of air. They

are designed to remove ultrafine dust, aerosols and viable organisms. Applications are found within Cleanrooms, in hospital operating theatres and laboratories, but also in the micro-electronics, optical and precision industries, the pharmaceutical and food industry.

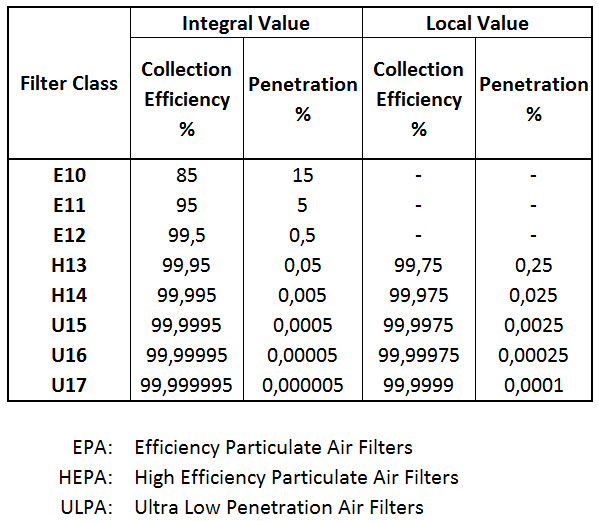

The new series of BS EN 1822 “High Efficiency Air Filters (EPA, HEPA and ULPA)” has been published in January 2011. The publication is also available in French as NF EN 1822:2010 and in German as DIN EN 1822:2010. The standard describes the factory testing of the filtration properties of absolute filters, i.e. Efficient Particulate Air filter (EPA), High Efficiency Particulate Air filter (HEPA) and Ultra Low Penetration Air filter (ULPA). For the in-situ testing of those filters under installed conditions the well-known, BS EN ISO 14644-3 remains valid.

The standard contains 5 parts: Part 1: Classification, performance testing, marking Part 2: Aerosol production, measuring equipment, particle counting statistics Part 3: Testing flat sheet filter media Part 4: Determining leakage of filter elements (scan method) Part 5: Determining the efficiency of filter elements

Working Group 1 of CEN/TC 195 “Air Filter for General Ventilation” has prepared the revisions and additions to the existing EN 1822. The new issue replaces the previous part 1 through 3 from 1998 and parts 4 and 5 from 2000. For the UK, the mirror committee MCE- 21 in BSI has cooperated on the new standard.

What is new? In Part 1 the classification of the filters H10 to H12 has been changed into E10 to E12. The intention of the name change into EPA filters it to clearly differentiate filters with only an integral or overall efficiency measurement. Group E filters cannot and must not be leak tested for classification purpose. Instead of an individual efficiency measurement, chapter 7.4.4 (and in Part 5, chapter 4.4) provide a method for statistical efficiency determination. The individual efficiency measurement and leak test remain mandatory for Group H and U filters.

Part 2 and 3 do not show essential changes.

Part 4 describes in the informative Annex D an alternate method for performance of the leak test (scan method) with a solid test aerosol, polystyrene latex (PSL). This is important, especially for the microelectronics, where in many cases the use of oily test aerosols is prohibited because of the outgassing of the material. The determination of the filter efficiency and classification remains, as per part 1 of the standard, to be executed with a liquid aerosol. In practice this means that whenever there is a mandatory requirement for PSL testing; only a scan test can be executed and efficiency and classification are determined with a liquid aerosol as a type test on a reference filter.

The informative Annex E describes an alternative method for leak testing H13 filters with a particle counter in the range of 0.3 - 0.5 m particles. Based on experience and a theoretical calculation of a defined leak an H13 filter with a local penetration of 0.25% (efficiency 99.75%), must have an overall efficiency of 99.9996% in the range of 0.3 - 0.5 m particles. This method can be used as an alternative in case of objections against the existing visual leak test as described in Annex A. Also for round and V-shaped H13 filters, this is a good alternative method.

Part 5 shows the existing detailed description of the efficiency determination in the MPPS (Most Penetrating Particle Size) for absolute filters (made from micro fibreglass) and gives in chapter 4.4 a detailed description of the statistical method for the efficiency determination of EPA filters.

The introduction already mentions the need for different test methods for membrane filters and filters with charged synthetic media. Membrane media enjoy increased demand, mainly in the microelectronics, where different processes prohibit the use of micro fibreglass as it may cause unwanted release of boron. Membrane media have a MPPS below 0.1 m. PTFE membrane media has a MPPS of 0.07 m (70 nanometre).

The informative Annex A describes two methods to test absolute filters with membrane media. Because the lower detection limit for particle counters is 0.05 m, a direct determination of the MPPS is only possible with a CNC (condensed nucleus counter). For alternative use of a laser particle counter and a 0.14 m DEHS aerosol a calculation and reporting example is given.

The normative Annex B describes the efficiency measurement and classification of absolute filters, using synthetic media with an electrostatic charge. Synthetic media with a nominal efficiency up to 99.95% are currently available in the market. High efficiencies are obtained by spinning finer fibres and providing an electrostatic charge. These synthetic media are offered as an alternative for absolute filters with micro fibreglass. The “permanent” electrostatic charge is discharged over time by neutralisation with collected dust particles, especially when these aerosols are sub-micron or charged particles. For EPA, HEPA and ULPA filters, which are selected for a guaranteed initial efficiency for use in critical applications such as health care, pharmaceuticals and industry and which are supposed to keep their efficiency for many years to come, this effect needs to be considered already in the measurement of efficiency and classification. Additions of 20% or more synthetic fibres to the absolute filter paper make the Annex B normative.

For measurement of the discharge the method of EN779:2002 Annex A has to be used. The filter needs to be identified with a label mentioning the percentage of synthetic fibres and the efficiency and classification under discharged condition, for example: “Efficiency 99.98% for MPPS in discharged condition as per Annex B of EN 1822-5:2010 “ “Filter class H13 as per EN 1822-1 and Annex B, EN1822-5:2010.”

Optionally it is possible to add: “Efficiency 99.998% for MPPS in new, charged condition as per Annex B of EN 1822- 5:2010 “

|